About loam as a building material

• Advantages and disadvantages of loam

• Improving the indoor climate

Earth used as a building material is often given different names. Scientifically referred to as loam, it is a mixture of clay, silt (very fine sand), sand, and sometimes larger aggregates like gravel or stones.

When speaking of handmade unburnt bricks, the terms of „mud bricks“ or „adobes“ are usually employed, when speaking of compressed unburnt bricks the term „soil blocks“ is used. When compacted within a formwork, it is called „rammed earth“.

In comparison to common industrialised building materials, loam has three disadvantages:

Loam is not a standardised building material

Depending on the site where the loam is dug out, it has different amounts and types of clay, silt, sand and aggregates. Therefore, its characteristics may change from site to site and the preparation of the correct mix for a specific application might also change. It is necessary to know the specific composition of loam to be able to judge its characteristics and change these by additives when necessary.

Loam mixtures shrink when drying out

Due to evaporation of the water used to prepare the mixture (which is required to activate its binding strength and to achieve workability) shrinkage cracks will occur. The linear shrinkage ratio is usually between 3% and 12% with wet mixtures (such as those used for mortar and mud bricks), and between 0.4% and 2% with drier mixtures (used for rammed earth, compressed soil blocks). The shrinkage can be reduced by reducing the clay and the water content, by optimising the grain size distribution and with the use of additives.

Loam is not water-resistant

Loam has to be sheltered against rain and frost, specially in its wet state. Earth walls can be protected by roof overhangs, damp proof courses, appropriate surface coatings etc.

On the other hand, loam has many advantages in comparison to common industrial building materials:

Loam balances the air humidity

Loam is able to absorb and desorb humidity faster and to a higher extent than all other building materials. Therefore, it balances indoor climate. Experiments at the Forschungslabor für Experimentelles Bauen (FEB) (Building Research Institute) at the University of Kassel, Germany, demonstrated that when the relative humidity in a room was suddenly raised from 50% to 80%, unburnt bricks were able to absorb 30 times more humidity than burnt bricks in a period of two days. Even when standing in a climatic chamber at 95% humidity for six months, adobes do not get wet and loose stability, neither do they exceed their equilibrium moisture content, which is about 5% – 7% by weight. (The maximum humidity a dry material can absorb is called its equilibrium moisture content).

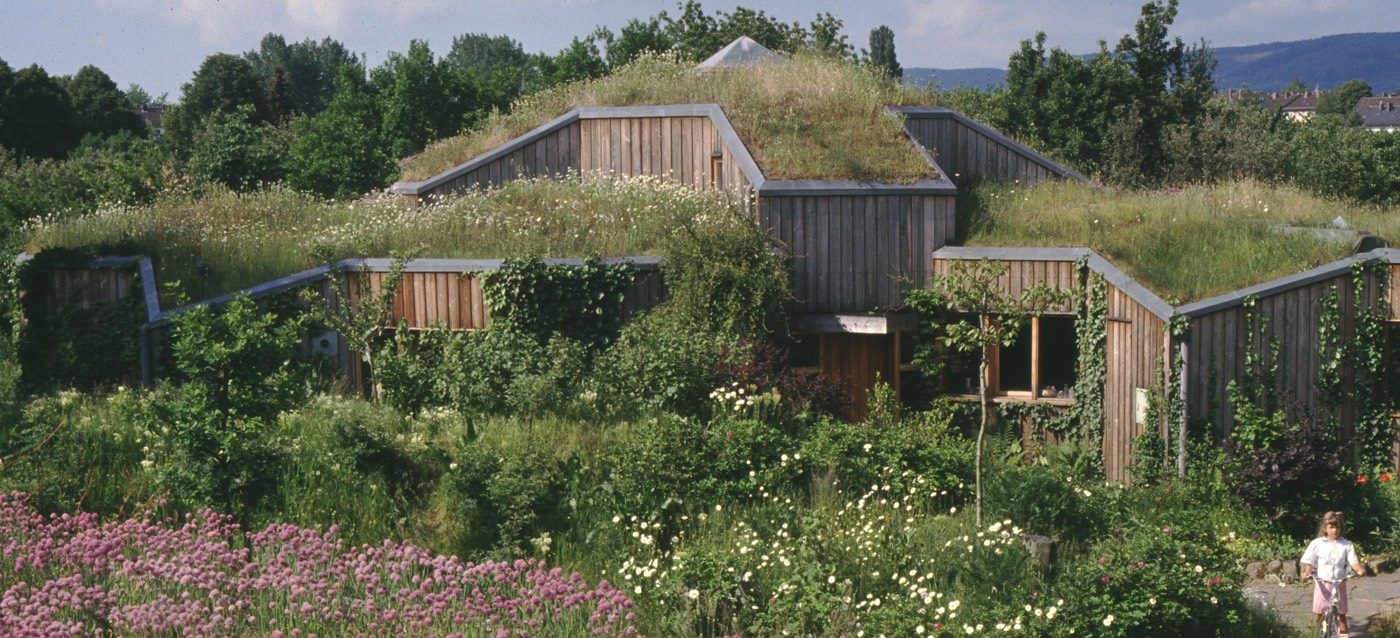

Measurements over a period of 8 years in a newly built house in Germany, where all interior and exterior walls are from earth, showed that the relative humidity in this house was nearly constant with 50% all over the year. It fluctuated by only 5-10%, thereby producing healthy living condition with less humidity in summer, and more in winter.

Loam stores heat

Like all heavy materials, loam stores heat. As a result, in climatic zones where the diurnal temperature differences are high, or where it becomes necessary to store solar heat gain by passive means, loam can balance the indoor climate.

Loam saves energy and reduces environmental pollution

To prepare, transport and handle loam on site, only about 1% of the energy needed for production, transport and handling of burnt bricks or reinforced concrete is used. Therefore, loam also produces hardly any environmental pollution.

Loam is always reusable

Unburnt loam can be recycled any number of times, and for ever. After soaking in water, old dry loam can be reused. Thus, loam can never be a waste material that harms the environment.

Loam saves material and transportation costs

Often clayey soil is found on site and the soil excavated for foundations can be directly used for earth construction. If the soil does not contain enough clay, some clayey soil has to be added, while if too much clay is present, sand has to be added. In comparison with other building materials costs can be greatly reduced by using the excavated soil. Even if this soil is transported from other construction sites, it is usually much cheaper than industrial building materials.

Loam is ideal for self-help construction

Earth construction techniques can usually be executed by nonprofessionals with just one experienced person controlling the construction process. The techniques are labour intensive and need inexpensive tools and machines, and are ideal for self-help work.

Loam preserves timber and other organic materials

Owing to its low equilibrium moisture content of 0.4% to 6% by weight, and its high capillarity, loam conserves timber elements that are in contact with it, as it keeps the wood dry. Normally, no fungus or insects will destroy such wood, since insects need a minimum of 14% to 18% humidity, fungus more than 20% humidity to live (Möhler 1978, p. 18). Similarly, loam can preserve small quantities of straw mixed within it.

However, if lightweight straw loam with a density of less than 500 – 600 kg/m3 is used, this preserving ability of loam may not be sufficient due to the high capillary of the straw when used in such high proportions. In such cases, the straw might rot, if it remains wet over a long period.

Loam absorbs pollutants

It has often been said that earth walls help to clean polluted indoor air, but until now, this has not yet been scientifically proved. It is a fact that earth walls can absorb pollutants dissolved in water. For instance, a demonstration plant exists in Berlin-Ruhleben which removes phosphates from 600 m3 of sewage per day using clayey soil. The phosphates are bound by the clay minerals and extracted from the sewage. The advantage of this procedure is that, as there are no foreign substances left in the water, the phosphorous are converted to calcium phosphate and can be reused as fertiliser.

Improving the indoor climate

General

In moderate and cold climates people usually spend about ninety per cent of their time in closed buildings. So the indoor climate is very important for their well-being. Their comfort depends on room air temperature, air movement, air humidity, radiation to and from surrounding objects, and the pollution of the air.

If the temperature is too high or too low, it is realised at once by the inhabitants, but the negative influence of too high or too low humidity is not common knowledge. The air humidity inside rooms exerts a significant influence on the health of the inhabitants, and earth has the ability to balancing indoor air humidity like no other building material. This recently investigated fact is described in detail later in this section.

Air humidity and health

From the research done by Grandjean (1972) and Becker (1986) we know that a relative humidity of less than 40% over a long period may dry out the mucous membrane (slime film) which can lead to decreased resistance to colds and related diseases. This is because normally the mucous membrane of the epithelial tissue within the trachea absorbs dust, bacteria, viruses etcetera and returns them to the mouth by the wavelike movement of the epithelial hair. If this absorption and transportation system is disturbed by drying out, these foreign bodies reach the lungs and may cause health problems. (See fig.)

From the research done by Grandjean (1972) and Becker (1986) we know that a relative humidity of less than 40% over a long period may dry out the mucous membrane (slime film) which can lead to decreased resistance to colds and related diseases. This is because normally the mucous membrane of the epithelial tissue within the trachea absorbs dust, bacteria, viruses etcetera and returns them to the mouth by the wavelike movement of the epithelial hair. If this absorption and transportation system is disturbed by drying out, these foreign bodies reach the lungs and may cause health problems. (See fig.)

A high relative humidity of up to 70% has many positive influences: it reduces the fine dust content of the air, activates the protection mechanisms of the skin against microbes, reduces the life of many bacteria and viruses, and reduces odour and static change on the surfaces of objects in the room.

A relative humidity of more than 70% normally feels unpleasant probably because of a reduction in the oxygen intake of the blood in warm-humid conditions. Increasing rheumatic pains are observed in cold humid air. Fungus formation increases significantly in closed rooms when the humidity rises above 70% or 80%. Fungus spores in large quantities can lead to various kinds of pain and allergies. From these considerations, it follows that the humidity content in a room should be a minimum of 40% and not more than 70%.

This text is an extract from Gernot Minke’s book „Building with Earth.“